Organic Fertilizer Powder Production Line For Poultry Manure And Municipal Waste

Raw Materials of Organic Fertilizer Production Line

2. Animal manure: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.

3. Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue, etc.

4. Home scrap: food waste, the roots and leaves of vegetables, etc.

5. Sludge: the sludge of the river, sewer, etc.

Basic Raw Materials, Adjuvants and Formulation:

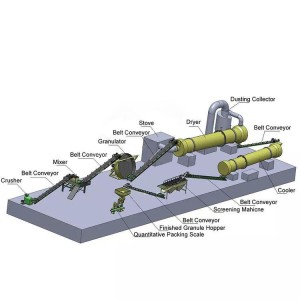

Working principle

* Compost

Organic raw materials are regularly carried out through the dumper. There are several parameters that affect compost, namely particle size, carbon-nitrogen ratio, water content, oxygen content and temperature. Attention should be paid to:

1. Crush the material into small particles;

2. The carbon-nitrogen ratio of 25-30:1 is the best condition for effective composting. The more types of incoming materials, the greater the chance of effective decomposition is to maintain the appropriate C:N ratio;

3. The optimal moisture content of compost raw materials is generally about 50% to 60%, and Ph is controlled at 5.0-8.5;

4. The roll-up will release the heat of the compost pile. When the material decomposes effectively, the temperature decreases slightly with the overturning process, and then returns to the previous level within two or three hours. This is one of the powerful advantages of the dumper.

A vertical strip grinder is used to crush compost. By crushing or grinding, blocky substances in compost can be decomposed to prevent problems in packaging and affect the quality of organic fertilizer.

* Sieve

The roller sieve machine not only removes impurities, but also selects unqualified products, and transports compost to the sieve machine through a belt conveyor. This process process is suitable for drum sieve machines with medium size sieve holes. Sieving is indispensable for the storage, sale and application of compost. Sieving improves the structure of compost, improves the quality of compost, and is more beneficial to subsequent packaging and transportation.

* Packaging

The sieved fertilizer will be transported to the packaging machine to commercialize powdery organic fertilizer that can be directly sold through weighing, usually with 25 kg per bag or 50 kg per bag as a single packaging volume.