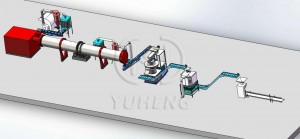

3-5 T/H Sunflower Husk Hemp Straw Alfalfa Grass Sawdust Biomass Wood Pellet Production Line

Wood pellet production line

Our pellet plants apply for different biomass materials, such as wood, straw, rice husk, sugarcane, peanuts shell, grass and etc. As for the applications, the pellets made by pellet plant can be used as biofuel. Generally, a complete wood pellet plant includes wood chipper, wood crusher (also hammer mill), rotary dryer, wood pellet machine, counter flow cooler, packing machine, electric control system, etc. We can customize every project according to clients' raw material and capacity.

|

* Production Line Name: Biomass Wood Pellet Production Line

|

||||

|

* Capacity Of This Line: 1-10 T/H

|

||||

|

* Function Description: Making Wood Pellets, Biomass Pellets.

|

||||

|

* Type Of Raw Material: Wood Logs, Sawdust, Planks, Straws, Other Biomass Wastes Etc.

|

||||

|

* Final Pellet Size: 6/8/10/12mm Or Other Customized Sizes.

|

||||

|

* Main Machines Used: Wood Pellet Mill, Drum Type Wood Chipper, Hammer Mill, Rotary Drum Type Drying Machine, Counterflow Cooler,Automatic Packing System.

|

Comprehensive wood crusher

Comprehensive wood crusher is a machine for producing wood chips. It applies for various raw material, such as, wood pallet, building template, wood logs, timber, furniture waste etc.

Raw materials for making wood pellet should have water content between 10% and 18%. Dryer machine can lower the water content to required level, so as to improve the molding rate and pellet quality..

Wood pellet machine (also wood pellet mill) is a machine that is used to press sawdust and other crushed biomass material powder into biomass wood pellets.

The high temperature in pellet mill will heat up the pellets. Usually they can cool down naturally. But if you want to pack them right after production, a pellet cooler can improve the efficiency. Cooling can also increase the hardness of wood pellets.

If you produce wood pellets for sale or future use, packing them into bags is necessary. Packaging makes it convenient for storage and transportation, and protects wood pellets from water and air.

The above are components of small wood pellet plant. For specific situations, you don't have to collect all of them. For example, you can leave out the counterflow cooler and pellet packing machine if you produce wood pellet for self use. And the dryer is optional depending on your materials.

Application

Wood pellet production line applies for various biomass material, such as wood, sawdust, wood chips, straw, rice husk, peanut shells, bamboo, grass, alfalfa, sugarcane, coffee husk, etc.