Products

-

Single Column Robot Palletizer Swivel Arm Robot Palletizer

Rotary stacking is mainly used in beer, beverage, medicine and other industries production line back end stacking, with more than 180 degrees of rotation function, can be applied to multiple pallets stacking at the same time, flexible rotation, small area, there are many dimensions, performance can be compared to robot stacking.

-

Double Warehouse Limestone Gravel Clay Sand Field Bag Packing Machine

Sand weighing and packing machine, referred to as Sand packing machine, is specially used for packing sand, such as river sand, washed sand, coarse sand, medium sand, fine sand, very fine sand, molten sand, building sand, texture round sand, artificial sand, silty sand, washed color sand, sand, quartz sand and so on.

-

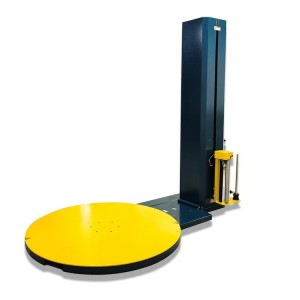

High Speed Rotate Stretch PE Film Pallet Wrapping Machine

The automatic pallet stretch film wrapping machine is suitable for the packaging of containers and bulk pallets of various goods.It can improve the logistics efficiency and reduce the loss in the transportation process. It has the advantages of dust-proof,moisture-proof and reducing the packaging cost.It has the advantages of simple operation, stability and reliability, uniform film spreading and beautiful packaging effect. It is an ideal choice to improve the packaging grade of products.

-

Separation Equipment Cassava Seed Corn Grain Stainless Steel Vibration Screening Machine

Vibrating screen can equip with single-layer or multi-layer screens to achieve the target of rating, impurity, removing powder, testing, washing, dehydration, etc.

Materials are put into the inlet of the screen machine by the feeder evenly and are divided into several products,unqualified sieve materials,qualified sieve materials through the multi-layer screen and all of them discharge from their own outlet. It can be used in the automatic work of the assembly line. -

400-500kg/h Sawdust Rice Husk Charcoal Pellet Briquette Making Machine

Charcoal Briquette Extruder Machine is using the screw extrusion principle, press the mixed material to certain shapes (cylindrical, hexagon, etc) and sizes with large intensity.

The machine is mainly composed by main engine and drive, easy to install and fix on the seat, with excellent rigidity and small vibration, can adapt to the poor working condition and bigger load fluctuation. Also, protect the motor, reducer, main shaft and other important parts effectively because of its smooth working condition. -

Small Scale Durable Smokeless Biofuel Padddy Husk Rucehusk Briquettes Machine

Sawdust rod making machine is often used to make sawdust, rice husks, bamboo powder and other biomass materials through high temperature extrusion into a diameter of about 50 mm.

The finished rod products,can be used as boiler fuel, can also be carbonized as smokeless barbecue charcoal.

-

3-5 T/H Sunflower Husk Hemp Straw Alfalfa Grass Sawdust Biomass Wood Pellet Production Line

A complete wood pellet plant includes wood chipper, wood crusher (also hammer mill), rotary dryer, wood pellet machine, counter flow cooler, packing machine, electric control system, etc. We can customize every project according to clients’ raw material and capacity.

-

25-50kg Valve Bag Dry Mortar Fly Ash Lime Powder Bagging Machine

Valve bag packaging machine is an automatic packaging equipment suitable for powdery, granular and other materials. It is widely used in food, chemical industry, building materials, daily chemicals and other industries.In the chemical and building materials industries, it is mainly used for the packaging of cement, bituminous coal powder fertilizers, pigments, coatings and other products; the quantitative packaging of valve bags of raw materials in some chemical plants is widely used.

-

High Quality industrial bag filter type dust collector

Baghouse dust collector, sometimes called baghouse collector or bag dust collector, is the most common type of air pollution control equipment used in any industrial application which requires dry dust control.

-

Bulk Jumbo Bag Unloading System FIBC Big Bag Discharge Station Machine

The bulk bag unloading station can handle the unpacking and unloading of large, granular, and small ton bags. Its structure is simple, high degree of automation, mainly composed of equipment brackets and guard plates, electric hoists (customer-owned cranes, forklifts, and other lifting equipment can also be used), ton bag hangers, bag clamping devices, beating, vibration, iron remover (optional), buffer bins. The electric control system is controlled by a control box or PLC. It is divided into two types, closed ton bag unloading station and openton bag unloading station.

It is widely used in petroleum, chemical, plastic, carbon black, mining, food additives, salt sugar, cement, and other industries. -

Automatic Bag Pulling and Sewing Machine for Packaging

Size:3600*1150*1900mm

Capacity:8-12bags/min

Air pressure : 0.5-0.7Mpa

Air consumption:10m³/h

Power:2Kw

Voltage:380V/50Hz

-

Rotary Drum Organic Fertilizer Granule Machine

The drum granulator is a molding machine that can manufacture materials into specific shapes. The drum granulator is one of the complete sets of equipment in the compound fertilizer industry. It is suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. The main working method is wet granulation of agglomerates. Through a certain amount of water or steam, the basic fertilizer is fully chemically reacted in the cylinder after the humidity is adjusted. Under a certain liquid phase condition, the rotation of the cylinder can make the material particles Produce squeezing force to reunite into balls.