YH-MDR Robot arm palletizer

| Technical parameters | Application characteristics | |

| model | KW-180 | Adopting advanced science and technology; Low failure rate; Host highly integrated; Servo motor drive; Gear transmission; Simple structure; Automatic oiling maintenance; Low noise; Various types of stacks. |

| Stacking range: | 20-50kg | |

| Bale stacking speed: (bags/hour) | 1000-1200 | |

| Stacking layers: | 1-12 layers | |

| Palletizing arrangements: | Flower stack or liushun stack | |

| Air supply pressure: | 0.6-1.0Mpa | |

| Power supply: | 380V 50HZ | |

| Power consumption | 5KW | |

| Maximum handling weight of the bag | 180kg | |

The whole machine includes the main body of the mechanical arm, the base, the gripper and the control cabinet.

Main body of the packaging machine

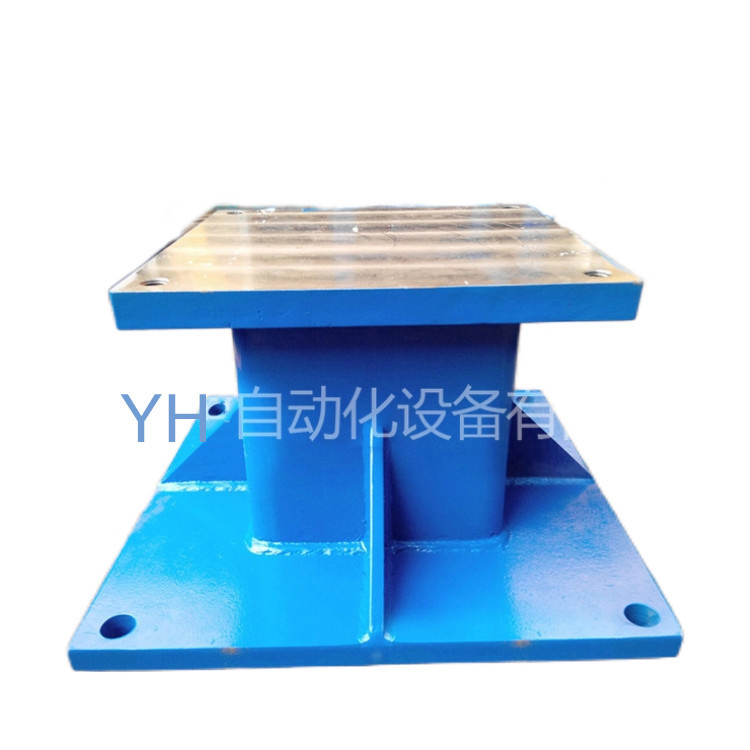

The base

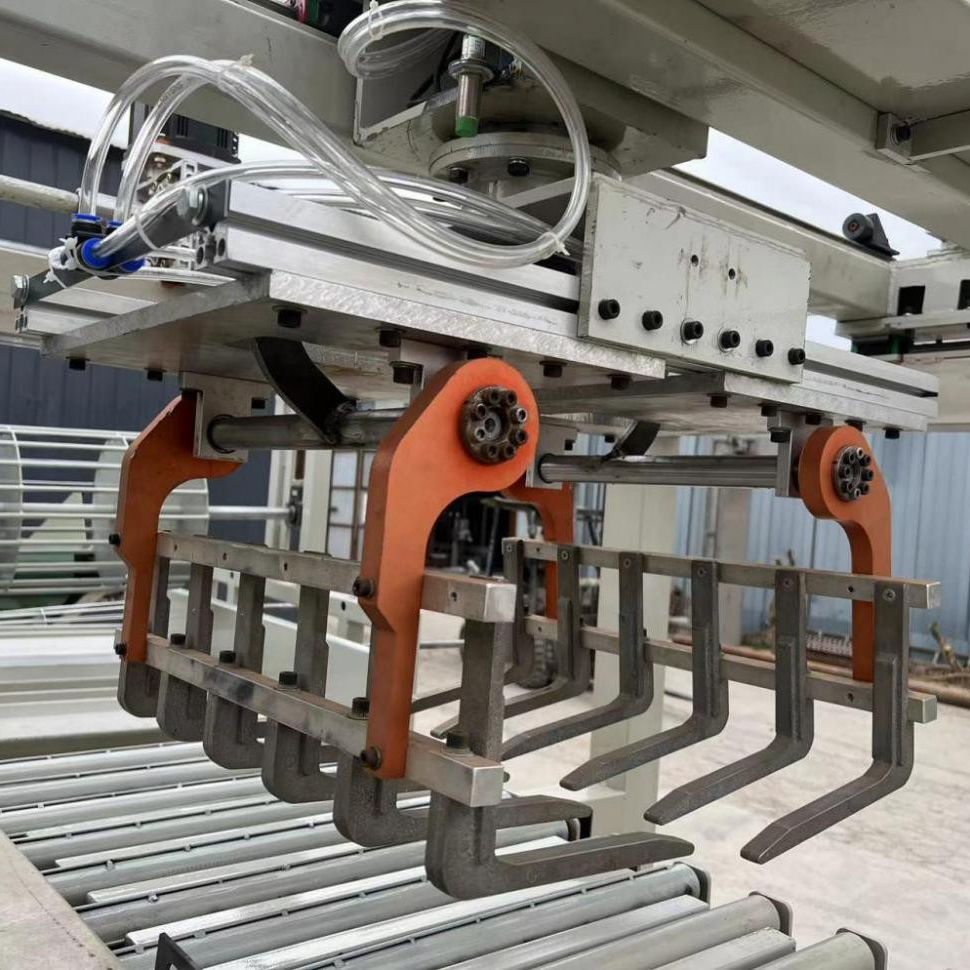

Mechanical gripper

1. The key structure of palletizing robot includes the base, waist, wrist and end actuator, etc., the six advantages of palletizing robot.

2. Improve employee safety at work: Due to the physical strength needed to load the tray, fatigue is avoided, thus solving the problems of fatigue distraction, injury, and repetitive and tedious exercise.

Enhance production flexibility: Each robot has an operator to organize multiple palletizing modes. The flexibility of the user interface can be modified, adding and adjusting palletizing modes as needed. The control system in the stacking robot production line has the advantages of simple structure, fast running speed, high stability and strong expansibility.

3. Production speed: Repeated motion at a constant speed allows trays to be assembled to increase the number of robots to higher speeds, depending on the production line and available space.

4. Enhance the quality of finished products on pallets: you can obtain high-quality surface treatment for each product. The tasks performed by palletizing robots thus solve the problems associated with human fatigue and distraction, which often lead to quality problems with the finished product.

5. Restricted workspace: Robot palletizers save more space than traditional palletizing systems. In addition, it can be programmed to work in small spaces, thus saving valuable ground space in the production area.

6. Lower operating costs: These systems can operate day and night with little lighting, reducing costs by turning them off lighting. Labour can be constrained because constraints require one person to run multiple machines simultaneously.