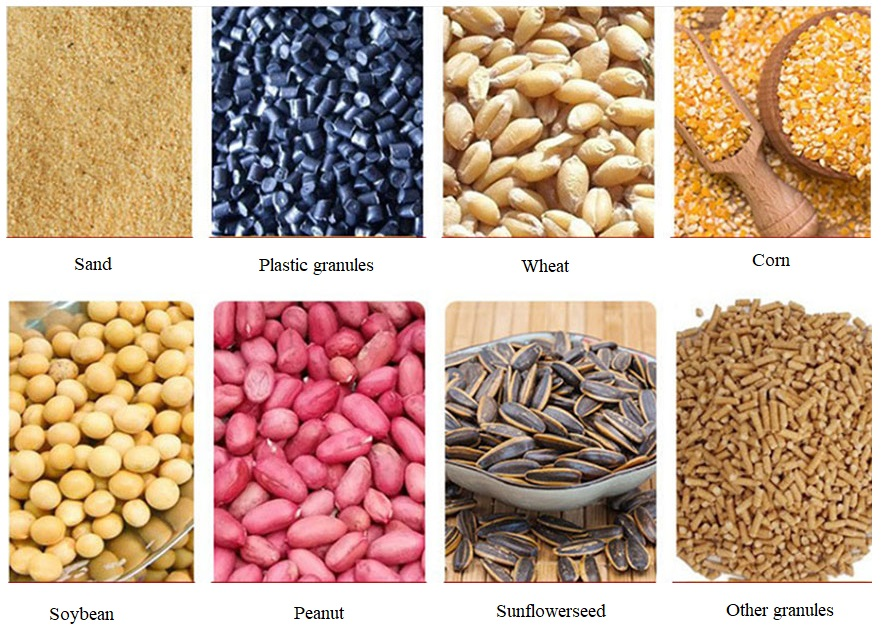

Semi Automatic 10kg 15kg 20kg 25kg Sunflower Seeds Pea Nuts Coffee Beans Rice Granule Weight Bagging Machine

This machine revolutionizes the use of servo motor to replace the traditional compressed air cylinders to achieve weighing and discharging maneuver. The working speed is literally doubled while keeps the accuracy at ±20g. Can achieve production rate at 40 tons per hour. It is suitable for packing various granular materials such as grains, seeds, plastic particles, beans, sugar, etc. To fulfill your specific requirement, we have initially designed a series of products, either with or without a weighing bucket, which can dramatically increase the measuring accuracy and packing speed. Furthermore, if higher packing speed is required, we can integrate two or more weighing buckets to increase productivity.

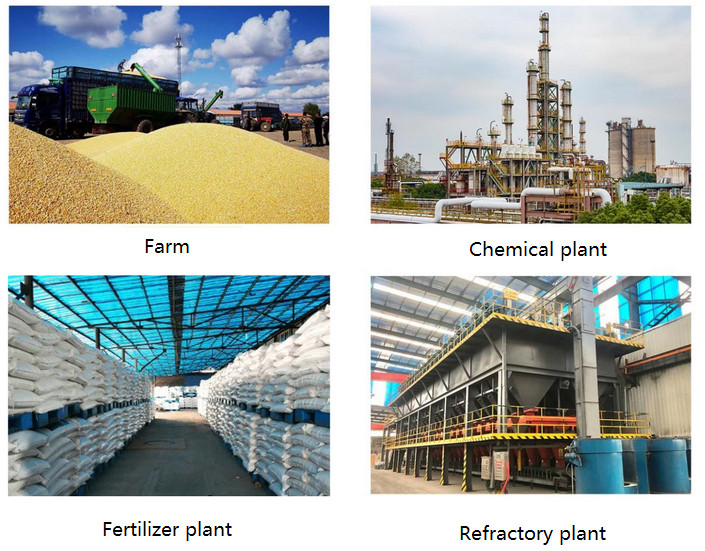

| Applicable materials and scenes | Wheat, corn and other grains, fertilizer granules, plastic granules, animal feed granules, sand, stones, and other granular materials with a diameter of 1-8mm. |

| Suitable for Mining, building materials, chemical industry, grain, fertilizer, feed, and other industries | |

| Weighing range (kg) | 20-50 |

| Weighing speed(bag/h) | 800-1000 |

| Weighing accuracy | 0.2% |

| Power supply | 380V/220V50Hz (Can be customized) |

| Power | 6Kw |

| Air consumption | 0.4~0.6Mpa 1m3/h |

| Working environment | 0℃~+40℃ |

| Sensor | ILGC-2000KG-BA * 4 (KeLi Electric) |

| Computer control instrument | A computer-programmed touch screen display (English, Chinese and French optional) |

| Pneumatic Components | Jiaerling |

| Manufacturing materials | The contact part with the packing material is made of carbon steel, which has good fluidity, wear resistance, corrosion resistance, and is easy to clean and hygienic. |

| Feeding mechanism | 3-stage arc valve feeding mechanism |

| Installation Dimensions (mm) | 3000*1550*4600 |

| Warranty | One-year warranty, lifetime maintenance service |

| Packing | Direct container shipment |

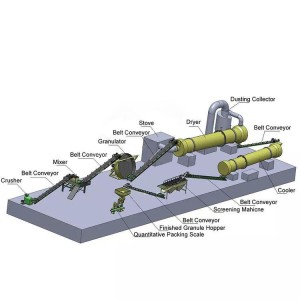

The control cabinet

A computer-programmed control instrument with High measurement accuracy, stable performance, and digital display. Chinese, English and French languages. Automatic setting of control parameters, automatic drop correction, super differential alarm, fault diagnosis, etc

The Feed opening

The contact part with the packing material is made of stainless steel, which has good fluidity, wear resistance, corrosion resistance, and is easy to clean and hygienic.

Servo weighing bucket

Servo motor feeding is used, which greatly accelerates the feeding speed. The granule packing machine has a special feeding method through a circular gate with three speeds: fast, medium and slow.

Manually place the bag over the lower outlet and toggle the bag clamping device, the control system receives the signal of the bags and drives the cylinder. The clamp clamps the bags. At the same time, it starts the feeding mechanism to feed the materials into the packing scale. The feeding mechanism is the belt feeding mechanism. The fast feeding (big head feeding) is used to feed the materials. When the target weight of the fast feeding is reached, the fast feeding can be done quickly. Material stops closing the feeding door, controlled by the instrument, slow feeding (small end feeding) for slow feeding. When the required target weight is reached, slow feeding stops, the belt opener opens automatically, the packaging bag falls on the conveyor automatically, and the conveyor delivers the packaging bag back to the seam outlet to complete a bag filling process.