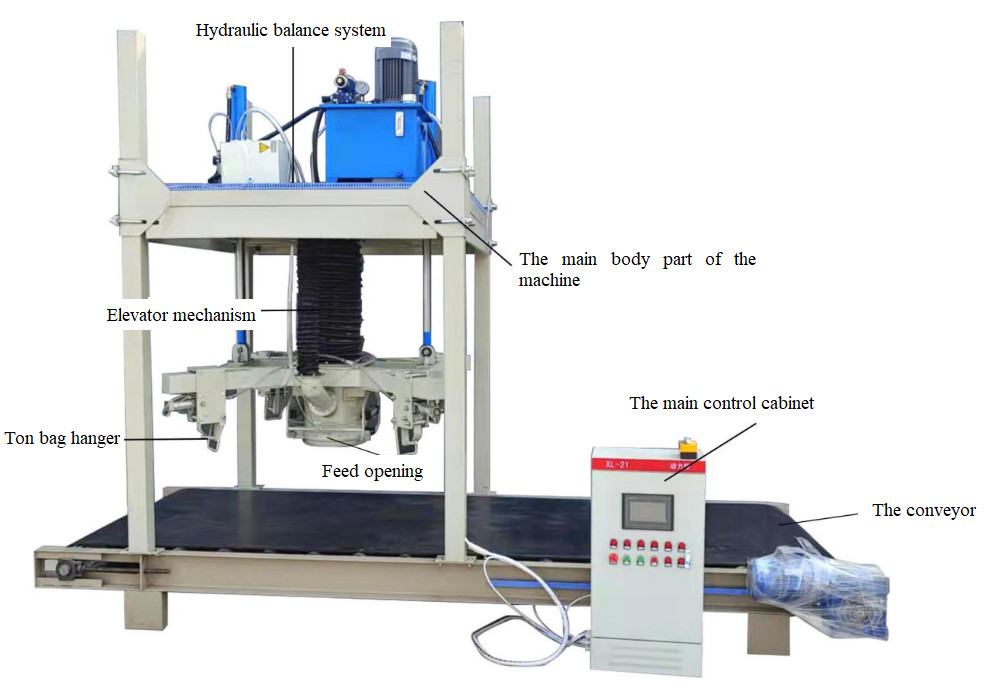

Automated Quantitative Packaging Machines for Food and Feed

Automated Quantitative Packaging Machines for Food and Feed,

,

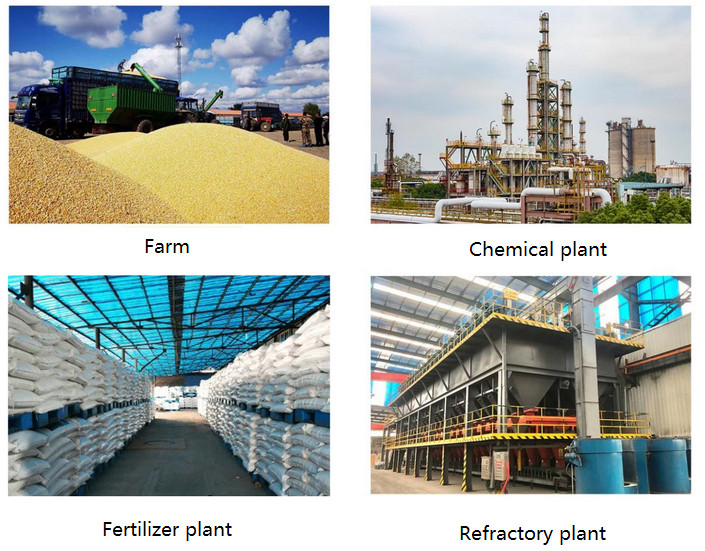

| Applicable materials and scenes |

Starch, cement, dry mortar, alumina powder, mineral powder and other Powder and super dry powder materials |

| Weighing range (kg) |

500-1000kg |

| Weighing speed(bag/h) |

20-40 |

| Weighing accuracy |

0.50% |

| Power supply |

380V/220V50Hz (Can be customized) |

| Power |

8.4Kw |

| Air consumption |

0.4~0.6Mpa 1m3/h |

| Working environment |

0℃~+40℃ |

| Sensor | ILGC2000KGBA*4 (KeLi Electric) |

| Computer control instrument |

A computer-programmed touch screen display (English, Chinese and French optional) |

| Pneumatic Components |

Jiaerling |

| Manufacturing materials |

The contact part with the packing material is made of carbon steel, which has good fluidity, wear resistance, corrosion resistance, and is easy to clean and hygienic. |

| Feeding mechanism |

3-stage arc valve feeding mechanism |

| Installation Dimensions (mm) |

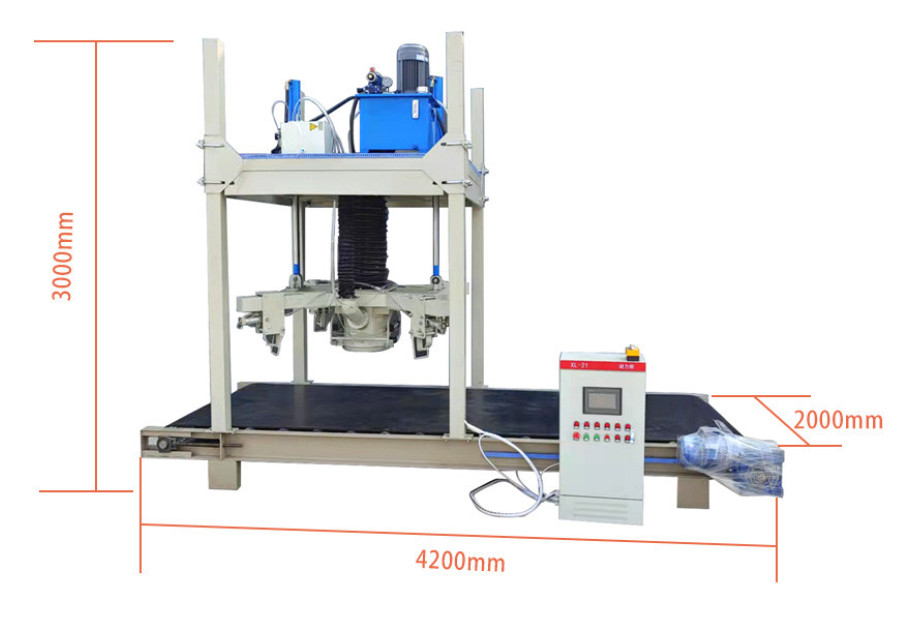

4200*2000*3000 |

| Warranty |

One-year warranty, lifetime maintenance service |

| Packing |

Direct container shipment |

A digital touch screen control instrument has high accuracy and stable performance—control parameters, automatic drop correction, super differential alarm, fault diagnosis, etc.

The contact part is made of stainless steel, which has good fluidity,

wear resistance, corrosion resistance, and is easy to clean and

hygienic. The rest is made of carbon steel.

| NO. | Name | Model | Brand | Unit | Qty | Unit price | Total price | Delivery cycle | Note |

| (RMB) | (RMB) | ||||||||

| 1 | The central body part of the machine | YH-1000P | Yu Heng | Piece | 1 | within 25 days | Size and output can be customized. | ||

| 2 | Belt conveyors | YH-SSJ | Yu Heng | Piece | 1 | within 25 days | Size can be customized. | ||

| 3 | Lifting mechanism | Yu Heng | Piece | 1 | |||||

| 4 | Ton bag hanger | Yu Heng | Piece | 1 | |||||

| 5 | The feed opening | Yu Heng | Piece | 1 | |||||

|

Total: RMB 65000.00 |

|||||||||

|

No. |

Model |

Brand |

Unit |

Qty |

Unit price |

Total price |

Delivery cycle |

Note |

|

(RMB) |

(RMB) |

|||||||

|

1 |

pocket switch |

YH |

Piece |

2 |

50 |

100 |

Shipped along with the main body part of the machine |

|

|

2 |

Clamping Cylinder |

YH |

Piece |

1 |

220 |

220 |

||

|

3 |

switching power supply |

YH |

Piece |

1 |

180 |

180 |

||

|

4 |

The electromagnetic valve |

YH |

Piece |

5 |

120 |

600 |

|

No. |

Model |

Brand |

Unit |

Qty |

Unit price |

Delivery cycle |

|

(RMB) |

||||||

|

1 |

A computer-programmed touch screen |

KunLunTongTai |

Piece |

1 |

1800 |

One day |

|

3 |

weighing instrument |

YH |

Piece |

1 |

2800 |

One day |

|

4 |

Weighing module |

YH |

Piece |

1 |

2200 |

One day |

|

5 |

Weighing sensor |

KeLi |

Piece |

1 |

2600 |

One day |

|

6 |

Inverter |

ChuangWei |

Piece |

1 |

1200 |

One day |

This automated quantitative packaging machine is designed to meet the needs of low-end customers in Asia, North America and Europe. It is suitable for all packaging bags, with fast coding speed, high coding accuracy and high automation, and is easy to operate, saving on labor costs.

The automatic quantitative packaging machine is mainly used for food and feed, and can be divided into two types: granular packaging machine and powder packaging machine. It can realize automatic quantitative packaging of various granular and powdered materials such as food, feed, chemical raw materials, etc., and can realize full automatic packaging production line and semi-automatic packaging production line.

This product has the following features and advantages:

1. Low error rate: The automatic quantitative packaging machine has a low error rate and a high packaging speed. It can realize accurate quantitative packaging of various materials, improve production efficiency and reduce labor costs.

2. High automation: The machine adopts PLC control system, which can realize automatic quantitative packaging, automatic feeding, automatic bagging, automatic weighing and other functions, reducing manual operations and improving work efficiency.

3. Easy operation: The machine has a simple operation process, which is easy to learn and use, and can be quickly put into use after installation.

4. Wide application range: The machine can be used for a variety of materials, such as food, feed, chemical raw materials and so on.

In addition, the automatic quantitative packaging machine uses advanced technology such as photoelectric detection, computer weighing and intelligent control, which has strong adaptability and is suitable for different types of packaging bags. It is a good choice for food, feed and other industries that need quantitative packaging.