Factory wholesale Automatic Grain Packaging Machine - YH-LX50 Super dry powder packing machine – Yuheng

Factory wholesale Automatic Grain Packaging Machine - YH-LX50 Super dry powder packing machine – Yuheng Detail:

| Applicable materials |

Powder material with water content below 5% |

| Weighing range (kg) |

20-50kg |

| Weighing speed(bag/h) |

180-240 |

| Weighing accuracy |

0.2% |

| Power supply |

380V/220V 50Hz (Can be customized) |

| Air consumption |

0.4~0.6Mpa 1m3/h |

| Working environment |

0℃~+40℃ |

| Sensor |

ILGC-200KG-BA (KeLi Electric) |

| Computer control instrument |

Computer programmed controller YH-3D |

| Pneumatic Components |

Taiwan Yadke |

| Dedusting |

Reserved dust removal port |

| Manufacturing materials |

The contact part with the packing material is made of stainless steel, which has good fluidity, wear resistance, corrosion resistance, and is easy to clean and hygienic. The rest is made of carbon steel. |

| Feeding mechanism |

Twin-packing auger |

| Installation Dimensions (mm) |

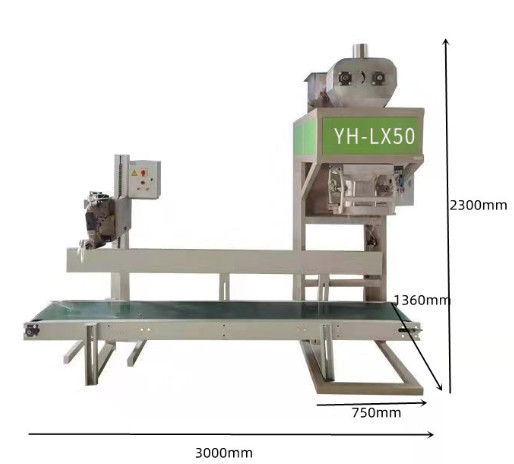

2300*1360*750 |

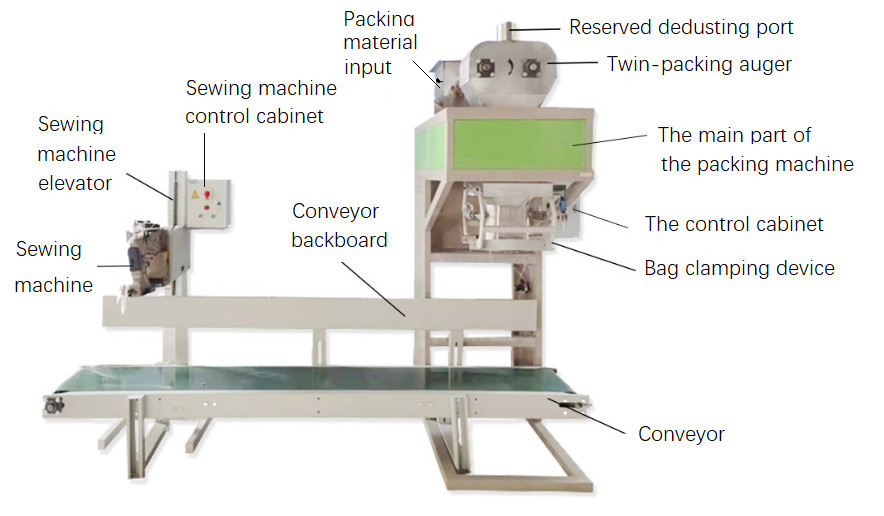

The whole machine includes the main body of the packaging machine, 3-meter conveyor, sewing charter plane and sewing package lift

A digital display control instrument has high accuracy, stable performance, built-in Chinese, English, and French languages, automatic control parameters settings, automatic drop correction, super differential alarm, fault diagnosis, etc.

The feed opening is made of stainless steel, wear resistance, high fluidity, hygienic, corrosion resistance, and extended equipment service life.

| NO. |

Name |

Brand | Unit | Qty | Dimensions(mm) |

| 1 |

The main packing part |

YH-LX50 | piece | 1 | 2300*1360*750 |

| 2 |

Conveyor |

Yuheng | piece | 1 | |

| 13 |

Pneumatic accessories |

Jarring | piece | 1 | |

| 4 |

Sewing machine |

2C sewing machine-Youtian | piece | 1 | |

| 5 |

Sewing bag elevator |

Yuheng | piece | 1 | |

| 6 |

Control cabinet |

Yuheng | piece | 1 | |

| 7 |

Control instrument |

YH-3D | piece | 1 | |

| 8 |

Motor |

Deshengxiang | piece | 1 | |

| 9 |

Reducing gear |

Mingji RV | piece | 1 | |

| 10 |

Electrical parts |

Zhengtai | piece | 1 | |

| 11 |

Weighing sensor |

Keli | piece | 1 | |

| 12 |

Feeder |

Deshengxiang | piece | 1 | |

|

Total priceRMB:22000( Can be customized according to customer needs) |

|||||

|

NO. |

Model |

Brand |

Unit |

Qty |

unit price |

total price |

delivery cycle |

Product Value |

|

(RMB) |

(RMB) |

|||||||

|

1 |

bag clamping switch |

YH |

piece |

2 |

50 |

100 |

shipped along with the main machine |

RMB1225 |

|

2 |

Clamping Cylinder |

YaDeKe |

piece |

1 |

220 |

220 |

||

|

3 |

switch power supply |

YH |

piece |

1 |

180 |

180 |

||

|

4 |

The electromagnetic valve |

YH |

piece |

4 |

120 |

480 |

||

|

5 |

sewing machine needle |

YH |

piece |

20 |

5 |

100 |

||

|

6 |

sewing needle board |

YH |

piece |

1 |

50 |

50 |

||

|

7 |

sewing needle bar |

YH |

piece |

1 |

35 |

35 |

||

|

8 |

sewing feed teeth |

YH |

piece |

1 |

60 |

60 |

|

NO. |

Model |

Brand |

Unit |

Qty |

Unit prices |

Delivery cycle |

|

(RMB) |

||||||

|

1 |

Weighing instrument |

YH |

price |

1 |

2800 |

1day |

|

2 |

Weighing module |

YH |

price |

1 |

2200 |

1day |

|

3 |

Weighing Sensor |

KeLi |

price |

1 |

2600 |

1day |

|

4 |

The inverter |

ChuangWei |

price |

1 |

1200 |

1day |

Scope of application:

Suitable for grain, feed, fertilizer, chemical flour and other bagged goods palletizing and handling industries.

Advantages:

Suitable for all packaging bags, automatic palletizing, fast palletizing speed, high palletizing accuracy, high degree of automation, simple operation, saving labour cost.

Machine configuration:

Main palletizing engine, coding roller conveyor, plastic conveyor, climbing belt conveyor, etc

The bucket elevator is suitable for lifting from low to high positions. After the feed enters the hopper through the shaking table, the machine automatically runs continuously and sends it upward. Transmission speed and lifting height can be adjusted according to the customer’s needs. The hoppers are designed and manufactured by our R&D team. PP non-toxic hopper makes this bucket elevator more widely used. The bucket size can be designed and manufactured according to the customer’s needs. It is suitable for food, medicine, chemical products, screws, nuts and other products that are needed for lifting and feeding. It can receive the signal from the packaging machine control panel to automaticly stop and start to save energy and cost.

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for Factory wholesale Automatic Grain Packaging Machine - YH-LX50 Super dry powder packing machine – Yuheng , The product will supply to all over the world, such as: Czech Republic, Kazakhstan, Ireland, We firmly think that we have the full capability to present you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!