2022 Good Quality Algorithm Goals Batch System - YH-PL Automatic weighing and baching system – Yuheng

2022 Good Quality Algorithm Goals Batch System - YH-PL Automatic weighing and baching system – Yuheng Detail:

1. Material: Q235 carbon steel, stainless steel according to customer requirements. Adopt a pneumatic actuator, reliable work, and simple maintenance

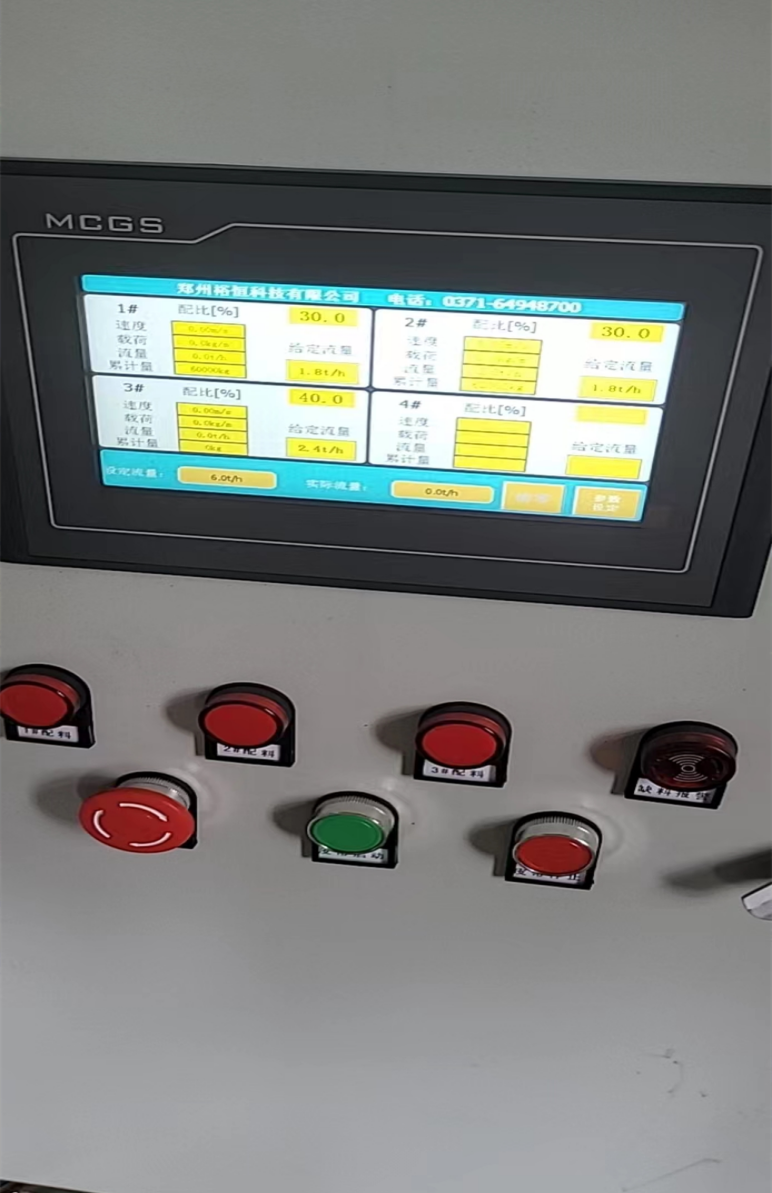

2. Using PLC high-speed sampling processing instrument communication and digital frequency conversion technology, with the automatic setting of control parameters and automatic drop correction. Adapting to different material characteristics can be continuous, simple, and flexible. Equipped with an RS-232C or RS485 communication interface, it can be connected to the upper computer.

3. Perfect exhaust system and good sealing performance, double sealing, prevent powder leakage, ensure high purity of the product

4. Especially designed feeding and bucket weighing mechanisms improve the flow speed of materials, fast batching speed, and high batching accuracy. It can be customized according to the customer’s needs

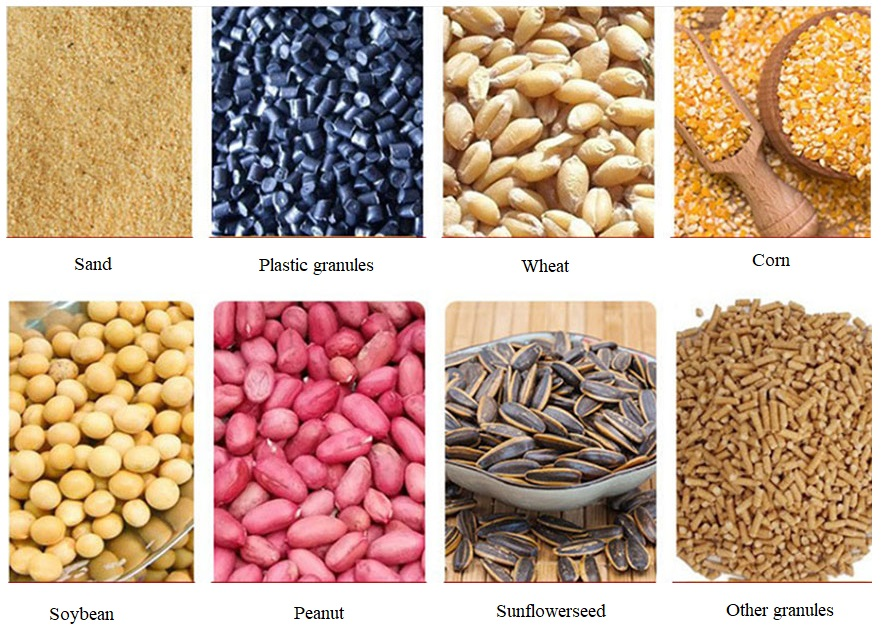

5. Applicable to grain, oil, feed, food, sugar, starch, flour, protein powder, fiber, skin, seed processing, chemical industry, chemical fertilizer, cement, storage, harbor, and other sectors in the production and operation of automatic quantitative ingredients. Wide quantitative range, high precision, a multi-purpose machine, and high efficiency。

6. Installation method: the batching machine is directly connected to the storage bin without adding the extra steel frame. It takes little space and is simple to install.

| Applicable materials | Granule, powder |

| Feeding method | Single bin quantitative feeding, multi-bin ingredients mixing |

| Batching speed(T/h) | 1T -100T |

| Batching accuracy | ≤±0.5% |

| Packing accuracy | ≤±0.2% |

| Batching species | Up to 16 different kinds |

| Installation method | On the ground or underground |

| Power supply | 380V / 220V 50Hz |

| Power consumption | 6Kw |

| Working environment | 0~+40℃ Rh≤90% |

| Sensor | PCS-1000KG-BA (KeLi Electric) |

| Computer-programmed controller | YH-PD66 (touchscreen) |

| Manufactured materials | The material of the contact part is made of stainless steel, which is worn-resistant, corrosion resistance, hygienic. It has properties of high fluidity, and extended equipment service life. |

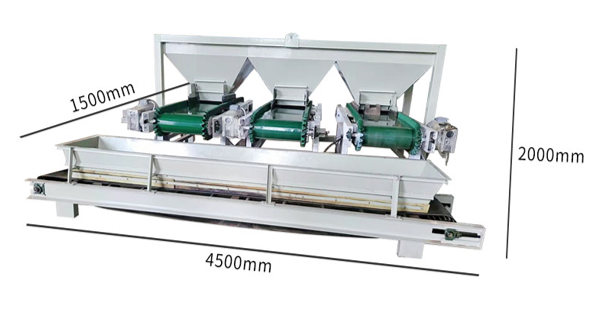

| Installation dimensions | For standard 3 bins configuration: 4500*1500*2000 (can be customized) |

| Installation method | The whole equipment set is directly hoisted to the installation site without adding any auxiliary steel frame, so that it occupies little ground space and is easy to install. |

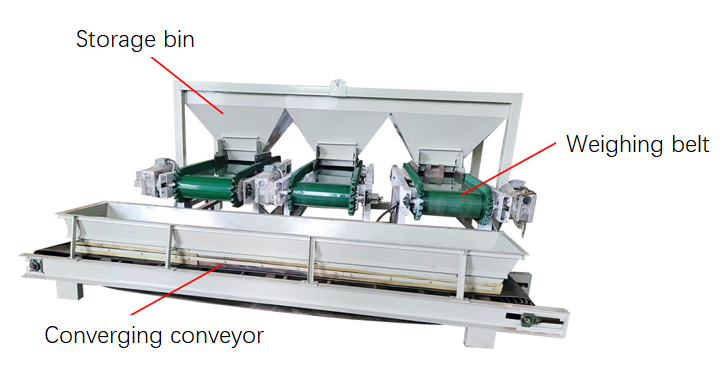

The machine includes a storage bin, a weighing belt scale, a converging conveyor, and a control cabinet

1. Storage bin

The capacity of the material storage bin, also known as the buffer bin, is customized according to the actual needs to be compatible with the workflow.

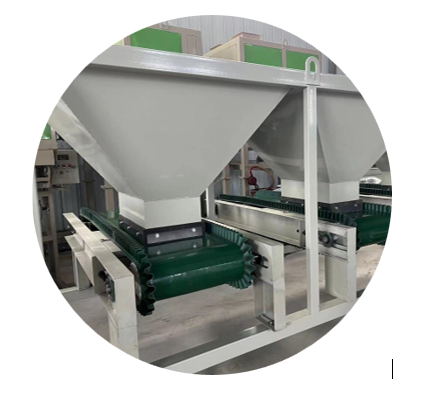

2. Weighing belt scale

Channel steel structure, with high rigidity and less dust area. There is no dust and erosive gas damage, high linearity, return to zero is the best choice of high-precision load sensor, suitable for application in wet occasions, no joint ring metering special skirt conveyor belt, dynamic zero value change is small.

3. Converging conveyor

4. Computer programmed control cabinet, high measurement accuracy, stable performance, digital display. It can automatically perform control, drop correction, super differential alarming, fault diagnosis, and other functions.

- Manufacturing materials: The shell adopts an advanced plastic spraying process, smooth and material contact parts, wear resistance, good mobility, high hygiene standard, corrosion resistance, and extended equipment service life.

|

Name |

Model |

Brand |

Unit |

Qty |

Unit Price (RMB) |

Total Price (RMB) |

delivery cycle |

Note |

| YH-PL Automatic weighing and batching system

|

YH-PL |

YH |

set |

1 |

17640 |

17640 |

25days |

The number of storage bins can be customized according to your requirements. |

PS: This machine can be customized according to the customer’s requirements; therefore, its price may vary.

Product detail pictures:

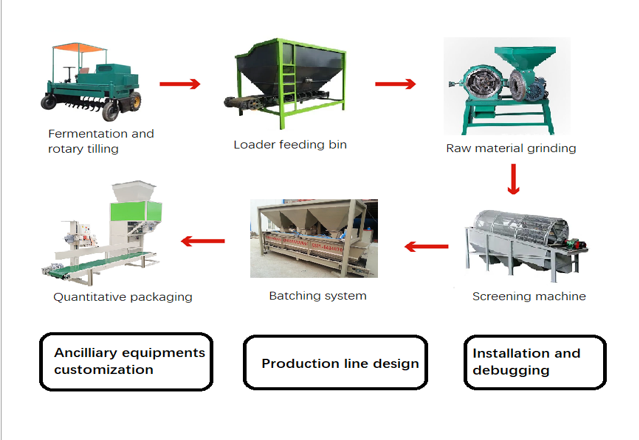

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for 2022 Good Quality Algorithm Goals Batch System - YH-PL Automatic weighing and baching system – Yuheng , The product will supply to all over the world, such as: Bangkok, luzern, Brasilia, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.