YH-PD50SG powder packing machine (dual-station)

| Applicable materials |

Powder, special-shaped lumps, briquette, lump coal, biomass particles, and other lumpy wet powder materials |

| Weighing range (kg) |

20-50kg |

| Weighing speed(bag/h) |

≥450 |

| Weighing accuracy |

0.2% |

| Power supply |

380V220V 50Hz (Can be customized) |

| Air supply |

0.4~0.6Mpa 1m3/h |

| Air source |

Choosing an air compressor with a capacity of 0.25 m3/min or above. |

| Air consumption |

0.4~0.6Mpa 1m3/h |

| Working environment |

-20℃~+40℃ |

| Sensor |

ILGC-200KG-BA (KeLi Electric) |

| Computer control instrument |

Computer programmed controller YH-D8 |

| Pneumatic Components |

Taiwan Yadke |

| Dedusting |

Reserved dust removal port |

| Manufacturing materials |

The contact part with the packing material is made of stainless steel, which has good fluidity, wear resistance, corrosion resistance, and is easy to clean and hygienic. The rest is made of carbon steel. |

| Feeding mechanism |

Belt 2-stage feeding feed |

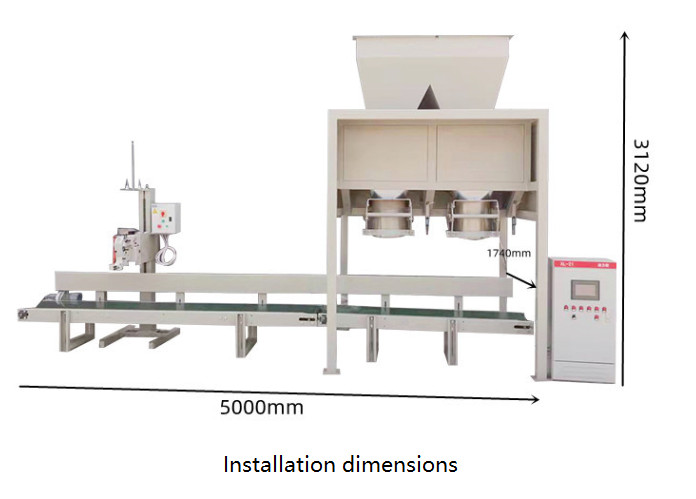

| Installation Dimensions (mm) |

5000*1740*3120 |

| Installation method |

The scale body is directly connected to the storage bin without additional steel frames. The installation process is simple and occupies little space on the ground. |

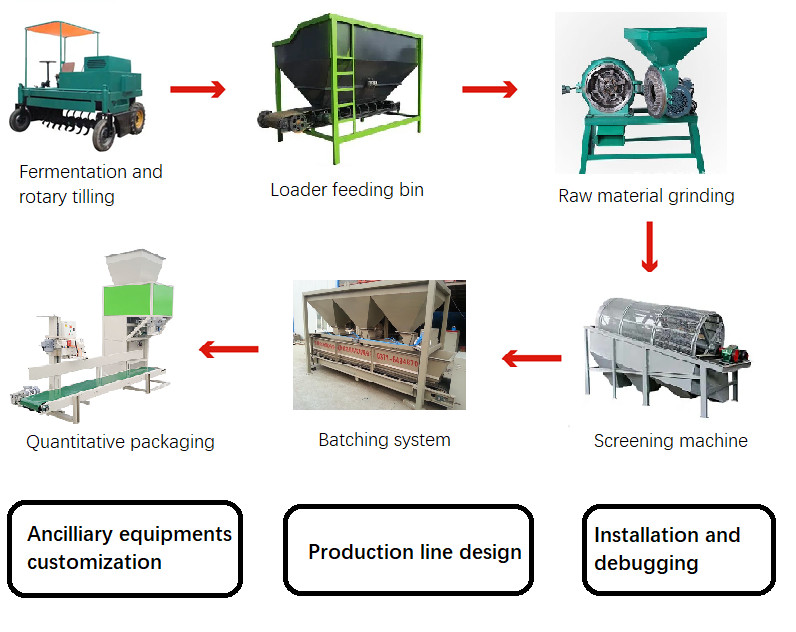

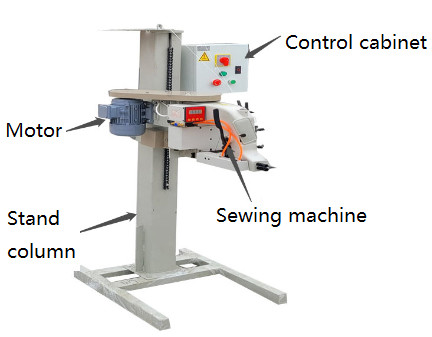

-The whole set of machines includes a double-station main weighing body (including control cabinet), 3-meter conveyor, 2-meter conveyor, sewing bag elevator, GK35-2C sewing bag machine

A computer-programmed control cabinet

High measurement accuracy, stable performance, digital display, automatic setting of control parameters, automatic drop correction, out-of-tolerance alarm, fault diagnosis and other functions.

Manufacturing materials:

The out layer of the machine adopts an electrostatic injection plastic process. The feed opening is made of smooth stainless steel, wear resistance, high fluidity, hygienic, corrosion resistance, and extended equipment service life.