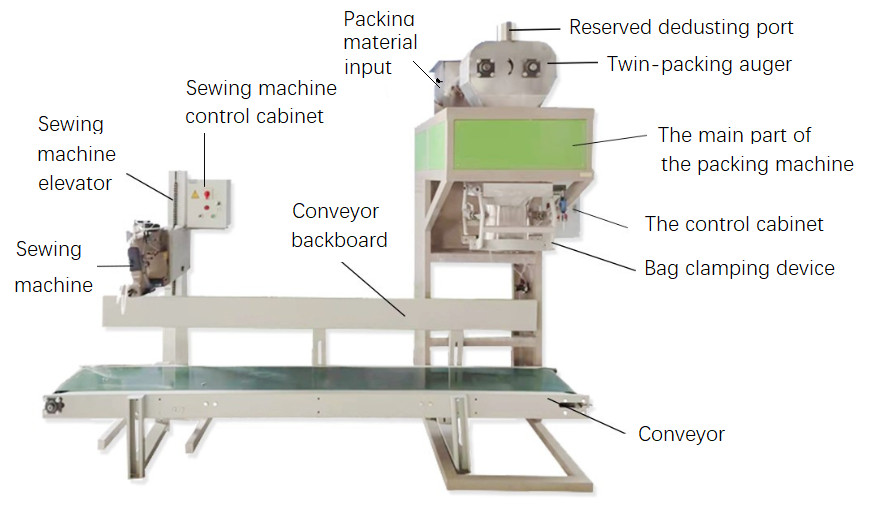

YH-LX50 powder packing machine (packing auger)

| Applicable materials |

Powder material with water content below 5% |

| Weighing range (kg) |

10-25kg |

| Weighing speed(bag/h) |

≧180 |

| Weighing accuracy |

0.2% |

| Power supply |

380V/220V 50Hz (Can be customized) |

| Air consumption |

0.4~0.6Mpa 1m3/h |

| Working environment |

0℃~+40℃ |

| Sensor |

ILGC-200KG-BA (KeLi Electric) |

| Computer control instrument |

Computer programmed controller YH-3D YHD8 |

| Pneumatic Components |

Taiwan Yadke, JELPC |

| Dedusting |

Reserved dust removal port |

| Manufacturing materials |

The contact part is made of carbon steel. |

| Feeding mechanism |

Twin-packing auger |

| Installation Dimensions (mm) |

2300*1360*750 |