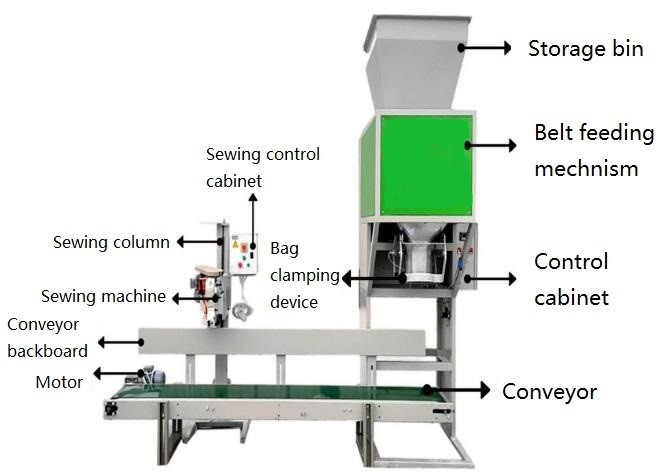

YH-B50 granule packing machine (with weighing bucket)

| Applicable materials | Granular materials have a diameter range of 1-8mm and a good fluidity |

| Gas consumption | 0.4~0.6Mpa 1m³/h |

| Work environment | -15℃~+40℃ |

| Sensor | ILGC250KGBA (KeLi Electric) |

| Controller | Computer programmed controller YHD8 YH3D |

| Pneumatic component | Taiwan Yadke, JELPC etc |

| Manufacturing materials | The contact part with the material is made of stainless steel, and The main body part is made of carbon steel. |

| Weighing range (kg) | 25-50kg |

| Packing speed (bag / h) | ≧400 |

| Precision | ±0.2% |

| Power supply | 380V / 220V 50Hz (customizable) |

| Power consumption | 1.5KW |

| Feeding method | 3-stage arc feed opening |

| Installation dimensions (mm) | 2600*720*800 |