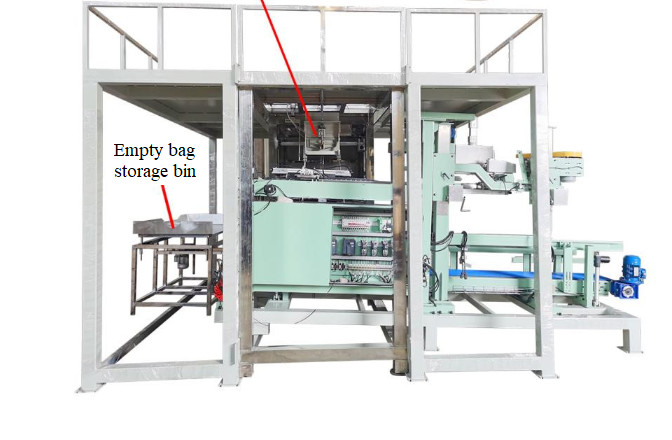

YH-AUTO automatic packing machine (dual-scale)

1: This machine integrates automatic bag covering, positioning, opening, filling, weighing, labelling, coding and sewing to perform an uncrewed packaging operation, which has high efficiency and less labour cost.

2: The drive core comprises PLC programming control, servo power, and pneumatic execution systems. The LCD touch screen man-machine interface completes the automatic control of weighing, bagging and packaging.

3: The setting and adjusting of packing parameters can be quickly done through the touch screen. The touch screen can store up to 10 different packing parameter settings. As a result, it is easy to call a new set of parameters when a new packing material is applied.

4: The actual feeding type (whether vibrating, belt or packing auger), the numbers of the weighing buckets, and whether to be combined with an automatic quantitative weighing and packing system. All of these can be customized according to the customer’s needs. The weighing bucket adopts a closed load weighing bucket, which can prevent material leakage and residual during weighing.

5: The machine adopts optical fibre identification signal transmission with higher precision with encoder confirmation function.

6: Optional palletizing robot can integrate packaging and palletizing, which has high work efficiency and low cost.

| Applicable materials | Granules, powders, ultra-dry powders |

| Gas source | It is recommended that you use a 20P air compressor |

| gas consumption | 0.4~0.8Mpa 1m³/h |

| working environment | 0~+40℃ Relative humidity≤90% |

| sensor | ILGC-200KG-BA(Keli Electric) |

| computer control instrument | Intelligent computer controller YH8D |

| Weighing method | Bucket weighing, hanging weighing. |

| manufacturing materials | Stainless steel |

| Weighing range (KG) | 25-60 |

| Weighing speed(bags/hour) | 400-600 |

| accuracy | ±0.2% |

| power supply | 380V 220V 50-60Hz(customizable) |

| Power (KW) | 10kw |

| feeding method | feeding method bucket elevator, belt, screw feeding |

| Installation size (mm) | 3000*3000*4600 |

| Machine weight (KG) | 4500 |

| NO. | Part’s name | Brand | Effect | Delivery period | Remarks |

| 1 | Storage bin | YH | store material | within 30 days | customizable |

| 2 | Packaging scale | YH | weighing | within 30 days | customizable |

| 3 | Automatic bag loading machine | YH | Bag loading and covering | within 30 days | customizable |

| 4 | Automatic sewing system | YouTian | Conveying + folding + coding + sewing + line cutting | within 30 days | customizable |

Zhengzhou Yuheng Technology Co., Ltd. manufactures stainless steel as the contact material between the host and the packaging machine. The platform, protective cover, safety fence, etc., are carbon steel.

Brief introduction of the automatic packaging production line

This packaging machine is highly automated, simple to operate and multi-functional. It will be designed, customized, installed, debugged and tested according to the customer’s needs. The system can continuously integrate the packing process and automatically perform weighing, bagging, positioning, filling, labelling, coding, folding, and sewing.

· Automatic feeding: the user can place a stack of bags in the bag storage bin, and the equipment will automatically take the bags.

· Automatic bag opening: the device will automatically open the bag

· Automatic bagging: the device will automatically cover the bag onto the automatic quantitative packing scale

· Automated quantitative packaging: After the bag is covered, the bag material will fall into the bag

· Automatic bag drop and bag transfer: After quantitative packaging, the equipment will drop the bag and transport it to the coding, folding and sewing device through the conveyor

· Automatic folding and automatic bag sewing: After the bag is transferred, the equipment will automatically fold the bag, label it, sew it and complete the packaging process.

Scope of application:

Suitable for grain, feed, fertilizer, chemical flour and other bagged goods palletizing and handling industries.

Advantages:

Suitable for all packaging bags, automatic palletizing, fast palletizing speed, high palletizing accuracy, high degree of automation, simple operation, saving labour cost.

Machine configuration:

Main palletizing engine, coding roller conveyor, plastic conveyor, climbing belt conveyor, etc